As an avid turkey hunter, I know that having the right turkey calls can make all the difference in bagging that big tom While you can buy manufactured box calls, making your own allows you to customize the design and tune it just how you like In this detailed guide, I’ll walk through the complete process of crafting a homemade turkey call box using basic tools.

Step 1: Select the Wood

Choosing the right wood is crucial for getting the proper acoustics from your turkey call. Here are some top options to consider:

-

Poplar – Affordable and easy to carve. Creates a mellow, muted cluck and yelp.

-

Cherry or Walnut – Dense hardwoods that produce clear, crisp game calls.

-

Cedar – Lightweight and very resonant for loud volumes.

-

Mahogany – Rich reddish color and projects sound well. A versatile choice.

I prefer using a softer wood like poplar or cedar for the box itself. For the paddle, pick a harder wood like maple, purpleheart or osage orange. This contrast creates the best acoustics. Shop for 3/4″ to 1″ thick boards about 5″ wide to get started.

Step 2: Cut the Box Pieces to Size

Using a miter or table saw, cut your box wood into lengths between 7-8 inches. This allows extra material for shaping. For the ends of the box, cut two pieces from a contrasting wood type around 3/4″ wide – I like maple or walnut accents.

Glue the end pieces onto the box blank using wood glue and clamps. Let it cure fully overnight before continuing.

Step 3: Shape the Box Exterior

Now it’s time to shape the exterior of the box. Draw diagonal lines marking a 5-10 degree slope on the sides. Carefully cut along these marks using a band saw, jigsaw or handsaw to create angled sides. Use a rasp and sandpaper to smooth and refine the box shape.

Cut an arched, curved shape from the top of the box to form the “roof” profile. Take your time to get a symmetrical arch on both sides.

Step 4: Add Decorative Details

Here you can get creative with decorative touches:

-

Wood burn a logo or pattern onto the box sides

-

Inlay a contrasting wood into the sides for accent stripes

-

Texture the surface with checkering or chisel work

-

Stain, paint or burn different colors

Step 5: Hollow Out the Sound Chamber

Layout the interior dimensions of the hollow sound chamber. Leave the walls approximately 3/8” thick to start. Use a Forstner bit to bore out most of the wood, hollowing the inside. Then finely shape and smooth the chamber interior with a carving knife, chisel and sandpaper.

Step 6: Create the Paddle Channel

On the underside of the box’s arched “roof”, carve a channel that extends side-to-side. Make it approximately 1/4” deep to allow the paddle to move freely. Use a knife, file or rotary tool to form the channel.

Step 7: Craft the Paddle

The paddle is key for producing sounds. Cut your chosen wood into a blank around 1 5/8” wide x 3/8” thick. On one end, draw the handle shape and use a band saw to cut it out.

On the bottom of the paddle, mark a curved radius. Use a sander to shape the rounded bottom edge. Smooth until flawless.

Step 8: Add Hardware

Drill a 1/8” hole in the paddle handle for the securing screw. On the box end, drill a larger countersunk hole for the screw to pass through and attach the paddle.

Place a coiled spring in the countersunk hole. Set the paddle in place and insert screw to hold while allowing tension.

Step 9: Install Bottom

Measure the interior base of the box. Cut a thin wood piece around 1/4” thick to fit snugly as the cover plate. Glue into place fully before moving forward.

Step 10: Tuning and Finish

The final steps are tuning and applying a protective finish:

-

With paddle attached, use sandpaper and carving tools to adjust the box interior and paddle position. Tweak until you achieve realistic turkey sounds.

-

Round over interior edges of the sound chamber for better acoustics. Test frequently while tuning.

-

Use an oil or spar varnish to seal and waterproof the wood. Apply multiple coats for durability.

Once your custom turkey call box is tuned and finished, you’ll be ready to bag that tom! With patience and practice, you can build a homemade game call that looks and sounds amazing.

Step 2: Wood Selection

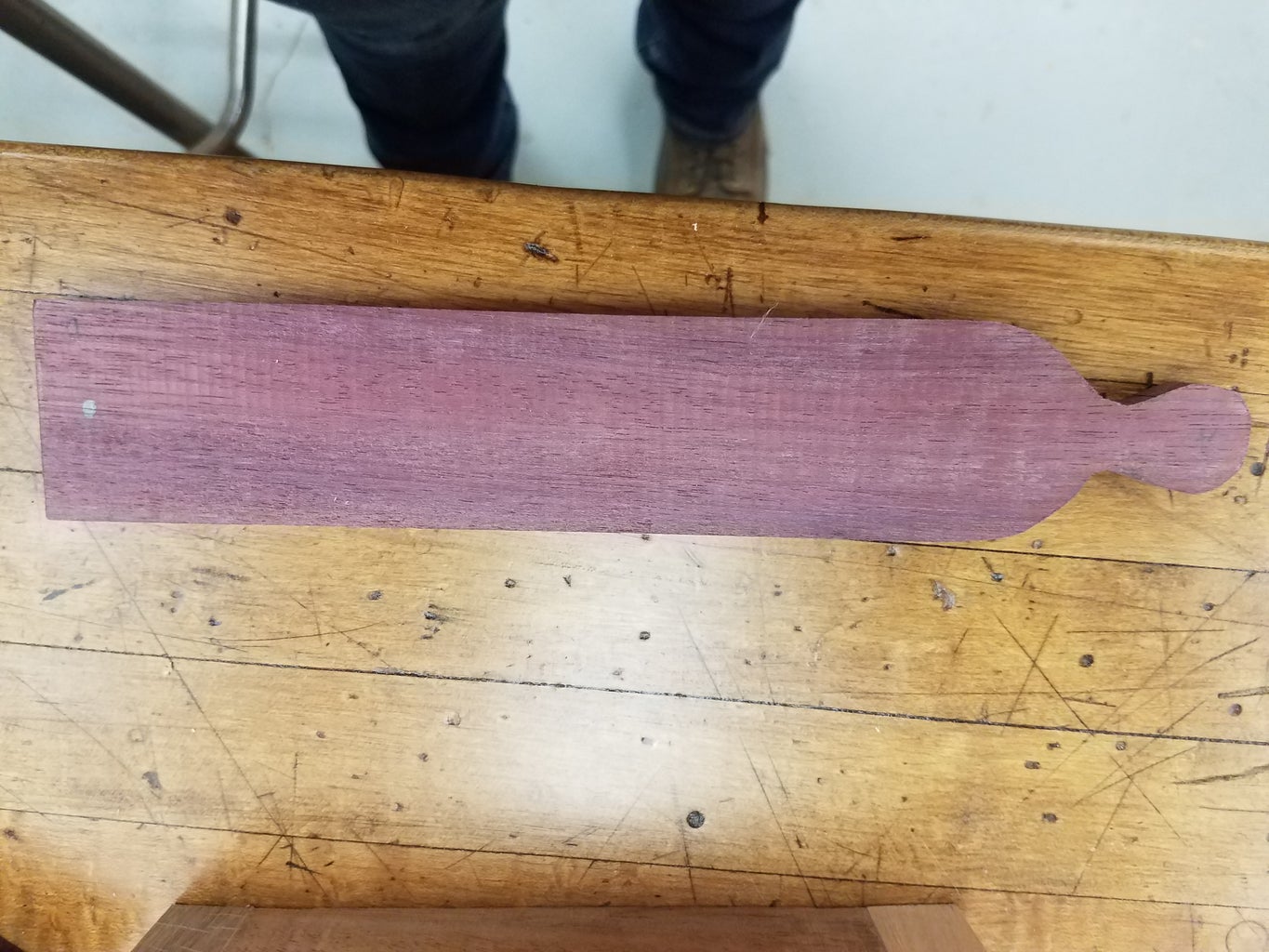

The first step in making a box call is selecting your wood. It is best to use a soft wood for the box and a harder wood for the paddle that has a nice straight grain to make tuning easier. A few good lumber choices for the box are: Poplar, Butternut, Mahogany, Walnut, Cherry, & Cedar. For Paddles: Maple, Walnut, Cherry, Purple heart, Zebra wood, Osage, and Yellow heart.

Step 9: Sound Chamber

Your ready to hollow out the inside of the box to create the sound chamber. Mark the top of my box where you want to hollow out. I usually stay inside the left and right sides of the call about 3/16″ or a little more this will not be the final thickness as that will come later in the tuning process, but It will give you a good starting point, without going to thin on the sides. The length of my sound chamber for this call will be 5 1/2″. Use a 1/2″ forstner bit with the tip ground off to do most of the work. Drill about 1 1/4″ deep into the box. Use a small sanding block to smooth up the inside but dont take off too much material leave that step for the tuning process.

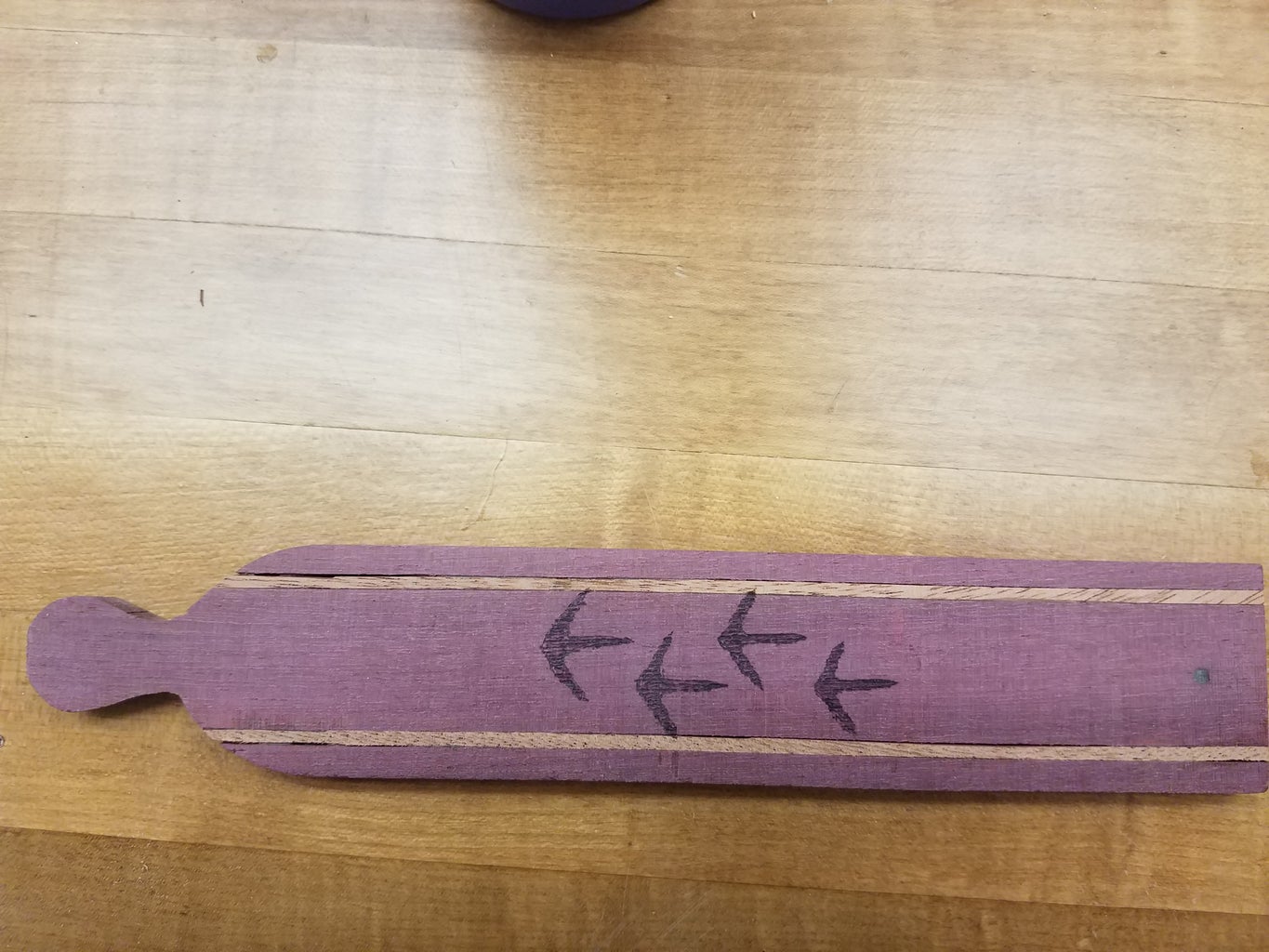

Create a channel at the rear of the box for the paddle. You can use a sharp knife, sanding disk or wood file, whatever works best for you.

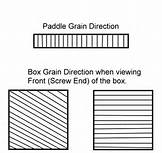

Ive chosen Purple Heart for my paddle and the end grain is very close to what Im looking for. It will work out fine. This blank was ripped down to 1 5/8″ wide. You can go with 1 5/8″ to 1 3/4″ width for you paddle. I need to rip down the blank to the thickness I want for the paddle. Ill rip it down to 3/8″ or a bit more to allow for sanding. Determine the front and rear then cut the handle out from the front. You can also have the option of putting inlays in to the top of the paddle. I choose to put mahogany inlays in mine to match the box. I also wood burned a design on top of the box which is also optional.

How to make a turkey box call

FAQ

What is the best wood to make a turkey box call?

Woods like cherry, walnut, and oak offer a balanced tone, capable of producing a wide range of turkey sounds with clarity and volume.Mar 18, 2024

What is the best box call for turkeys?

- Best Overall: Houndstooth Game Calls Dixie Hen Slate

- Best Box Call: Lynch World Champion Box Call

- Best Mouth Call: Woodhaven Custom Calls Ninja Ghost Mouth Call

- Best Slate: Zink Wicked Series Slate

- Best Push Button Call: Quaker Boy ‘Cyclone’ Easy Yelper

Can You Make your own box turtle Turkey call?

You can make your own box turtle turkey call if your state permits it—check with your state wildlife agency first. Be aware that no states allow you to kill the turtle for the shell—ever.

How do you make a turkey call?

Make a tube turkey call. Smooth the ends of a 3/4-inch (2 cm) PVC pipe coupler with sandpaper. Make a lip rest. Use the end of the PVC coupler to trace a circle onto a margarine tub’s plastic lid with a pencil. Cut out the plastic circle and then cut it in half to make 2 rests. You’ll need just 1 lip rest for this project.

How do you tape a turkey call?

Cut an oblong hole in the tape where it can wrap around the frame and give you a nice outside handhold to fit it to your mouth. Do not let the tape touch the latex. Slide your turkey call into the tape so the latex is exposed by the oblong hole you made. Fold the tape over and seal. Cut the tape to fit your mouth.