One common way to keep food fresh longer is to use gas flush packaging, which is also called Modified Atmosphere Packaging (or MAP). People usually put fresh meat in it that needs to stay fresh for a long time, like when they’re sending food to another country.

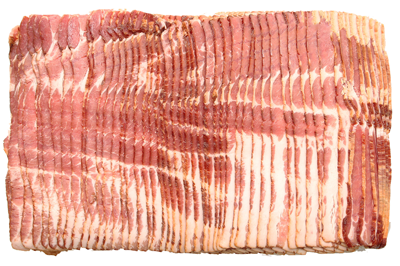

Crispy, smoky, salty bacon is one of life’s simple pleasures for many breakfast lovers. As a bacon enthusiast, you may have noticed some packaging touting that the bacon inside has been “gas flushed.” But what exactly does this term mean? I decided to dig into the details on gas flushed bacon and how it differs from traditionally packaged bacon.

What is Gas Flushed Bacon?

Gas flushed bacon refers to bacon that has been packaged using a preservation technique called modified atmosphere packaging (MAP) This involves removing oxygen from the package and replacing it with inert gases like nitrogen or carbon dioxide before sealing

The gases extend the shelf life of bacon by inhibiting bacteria growth The lack of oxygen creates an environment where aerobic bacteria have difficulty thriving This gives gas flushed bacon a longer shelf-life compared to traditionally packaged bacon.

The Benefits of Gas Flushed Bacon

There are several advantages that gas flushed bacon provides over regular vacuum-sealed bacon

-

Longer Shelf Life – The modified atmosphere gases significantly extend the shelf life of the bacon, keeping it fresh for weeks longer. This reduces waste.

-

Prevents Freezer Burn – The lack of oxygen prevents freezer burn, maintaining quality during frozen storage.

-

No Texture/Flavor Change – The gases do not react with the bacon, so no texture or flavor change occurs.

-

Food Safety – Inhibits bacteria growth like salmonella, reducing food safety risks.

-

Portion Control – Packaging allows easy access to just needed slices, unlike full vacuum packs.

For producers, the extended shelf life provides more sales flexibility and reduces losses. For consumers, it means less waste and consistently delicious bacon.

How is Gas Flushed Bacon Made?

Producing gas flushed bacon involves several steps beyond traditional bacon preparation:

-

Bacon is cured, smoked, and sliced as normal. High-quality pork belly is used.

-

Bacon slices are layered into pouches or trays.

-

Oxygen is removed from the packaging using a vacuum process.

-

Inert gases like nitrogen and carbon dioxide are injected to displace any remaining oxygen.

-

The bacon is sealed in the modified atmosphere packaging.

-

Packages are distributed to grocery stores, keeping the bacon fresh longer.

The specialized equipment involved in gas flushing enables normal oxygen levels to be reduced from 20-30% down to under 1% in the packaging. This is what extends the shelf life so remarkably.

How Should You Cook Gas Flushed Bacon?

Cooking gas flushed bacon is similar to traditional bacon. Stovetop and oven cooking methods both work well. Here are a few tips:

-

Pre-heat pans or ovens to avoid cold starts.

-

Cook to 165°F internal temperature to eliminate pathogens.

-

Adjust cooking time up slightly due to thinner slices of most gas flushed bacon.

-

Pat grease with a paper towel as gas flushed bacon releases more grease.

-

Bake in the oven on a rack over a foil-lined pan to collect grease.

-

Microwave in 30 second intervals if pan frying is not convenient.

The results are crispy, tasty bacon slices just like you’d expect! Proper handling and cooking enhances food safety.

Does Gas Flushed Bacon Really Last Longer?

With the oxygen removed from the packaging, absolutely – gas flushed bacon displays significantly longer shelf life compared to traditionally packaged bacon:

-

Vacuum-Sealed Bacon – Typically lasts 2-3 weeks in the fridge from the pack date.

-

Gas Flushed Bacon – Can last 6-8 weeks or longer from the pack date when gas flushed.

The gases prevent oxidative rancidity that leads to faster spoilage. Portion-controlled packaging also reduces waste from resealing partial packs.

When frozen, gas flushed bacon can last 3-6 months compared to 1-2 months for regular bacon. For maximum freshness, freeze gas flushed bacon in the original pack.

Is Gas Flushed Bacon Available Everywhere?

Gas flushed bacon availability is increasing along with consumer demand, but it is still less common than regular bacon. Here are some tips to find it:

-

Check premium butcher shops or meat counters at upscale grocers.

-

Specialty food stores like Whole Foods often stock gas flushed bacon options.

-

Online mail order steak companies offer gas flushed bacon packs.

-

Large wholesale clubs may carry their own gas flushed private label bacon.

-

Major bacon producers like Oscar Mayer, Smithfield, and Hormel are expanding gas flushed lines.

-

Search for “MAP bacon” or “gas flushed bacon” online to find more brands.

While not ubiquitous yet, gas flushed bacon can be found through some digging and is increasing in availability all the time.

Does Gas Flushing Change the Bacon’s Flavor?

One common question is whether the gas flushing process impacts the taste or texture of the bacon. Fortunately, the gases used for modified atmosphere packaging are inert and have no effect on the bacon itself.

The curing, smoking, and seasoning happen normally, producing the expected salty, smoky, savory bacon flavor we all love. The only difference is that gas flushed bacon delivers this taste for an extended period thanks to the protective packaging gases.

Is Gas Flushed Bacon More Expensive?

Typically, yes – gas flushed bacon does come at a slightly higher retail price point compared to traditional bacon. Here are some of the factors contributing to the cost difference:

-

Specialized equipment for gas flushing and MAP packaging.

-

Tighter quality control procedures.

-

Shorter production runs than high-volume traditional bacon.

-

Premium sourcing of high-quality pork belly.

-

Value-added preservation increasing shelf life.

For shoppers seeking maximum freshness and minimal waste, the extra upfront investment in gas flushed bacon can pay off in the long run. And extending shelf life provides options like buying in bulk when on sale.

The Takeaway on Gas Flushed Bacon

The use of gases like nitrogen and carbon dioxide to displace oxygen from bacon packaging results in markedly extended shelf life compared to traditional bacon packaging. This innovative gas flushing process keeps bacon fresh and flavorful for up to 2-3 times longer.

While gas flushed bacon costs a bit more than standard bacon, many bacon lovers find it worthwhile for the huge reduction in waste, convenience, food safety, and guaranteed deliciously crispy results. Looking for “gas flushed” or “MAP” on the label helps identify this newest generation of preserved packaged bacon.

How Does Gas Flush work?

The process of gas flush is pretty simple. So that a package can be sealed, inert gases like nitrogen or carbon dioxide are pumped into it. They “flush” the oxygen out of the pack because they are heavier than oxygen. This means that when the package is closed and sealed, only these inert gases are left inside, and the oxygen is gone.

The reason gas flush is used is because oxygen can cause meat to deteriorate more quickly. It lets foods break down through oxidation and is needed for the growth of aerobic microorganisms that can make food go bad.

In contrast, food will not react to the inert gases used in gas flush, which results in:

- extended product shelf life

- increased product integrity

- protection against discoloration

Injecting these gases into some products also makes a cushion-like puffer by blowing up the packaging. This helps protect fragile items like dry potato chips.

What Gases are Used?

There are several gases commonly used for gas flush packaging, each of which have different properties. The right mix of gases depends on what is being packed, so you should talk to your packaging supplier to find out what works best for you.

The Real Reason Why You Should Try Cooking Bacon In Water

FAQ

Is gas flushed meat safe?

What does gas flush layer bacon mean?

What is a gas flush?

What is the shelf life of gas flushed bacon?

What are the benefits of gas flushed Bacon?

One of the main benefits of gas flushed bacon is its extended shelf life. By removing oxygen from the packaging, the growth of bacteria and other microorganisms that can cause spoilage is inhibited. This means that gas flushed bacon can last longer in the refrigerator or freezer than traditional bacon.

Can you cook gas flushed Bacon in the oven?

Alternatively, you can also cook gas flushed bacon in the oven. Preheat your oven to 400°F and place the bacon on a baking sheet lined with parchment paper. Bake for 10-12 minutes or until it reaches your desired level of crispiness.

What is gas flush packaging?

Packaging that uses gas flush – also known as Modified Atmosphere Packaging (or MAP) – is a common packaging method used to extend the shelf life of food. It is most commonly used for fresh meat that will need to be preserved for a decent length of time – for instance for products being exported overseas. How Does Gas Flush work?

What is gas flushing?

Dr Roy Bickerstaffe, Professor of Food Biochemistry and Chair of the Lincoln University Research Committee, comments: “Gas flushing or gas packing is known as MAP or modified atmosphere packaging. It is widely used in the food industry for packaging products to preserve them longer in the modified atmosphere.